- Diameter (outside) [mm]

- 323.9 – 2235

- Wall thickness [mm]

- up to 25

- Length [m]

- 4 – 30

- Strength [MPa]

- up to 460 (X65)

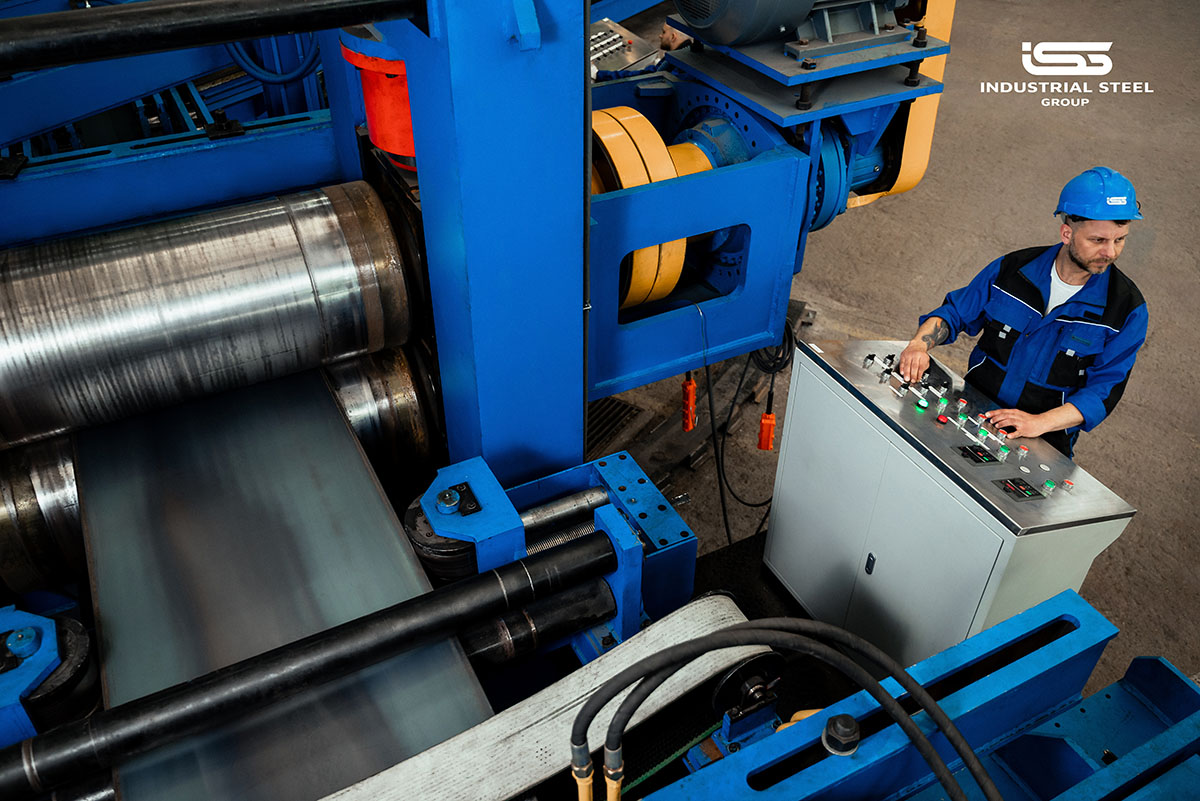

ISG — modern production of large-diameter spiral-welded pipes in Poland

ISG Industrial Steel Group is a Polish company that launched a new, modern production of large-diameter spiral-welded pipes in 2024.

ISG Industrial Steel Group provides maximum advantage to partners by offering quality pipe products in the metallurgical industry and convenient service at a competitive price.

Only fair competition can be the basis of business. This opens new opportunities for us and our partners. We aim to become the leading supplier of large-diameter electric-welded pipes in Europe. As a part of this strategy, we plan to expand our production and enter new markets.

We use advanced technologies and production methods, creating products that meet the most modern requirements.

Delivering impactful solutions, we empower our clientele to curtail expenditures and amplify operational efficiency

We use advanced technologies to create a convenient and efficient ordering and logistics system. This allows our customers to receive their orders quickly and easily, and our company to provide the best service.

Spiral-welded pipes are characterized by a higher level of strength compared to longitudinal-welded pipes. They are manufactured by the cold rolling method, allowing the production of pipes with high uniformity of metal structure.

The spiral seam ensures uniform distribution of stresses throughout the circumference of the pipe, making it more resistant to deformation and rupture. This makes spiral-welded steel pipes an ideal solution for use in infrastructure and industrial facilities where high strength and reliability are required

Spiral-welded pipes are used in various industries, such as:

Oil and gas transportation

Water supply, drainage, heating, sewerage

Transportation of hazardous and toxic materials, production of chemicals

Preventing soil erosion, strengthening the coastline and protecting areas from the negative effects of water bodies

Irrigation, water supply

Our pipes have the following advantages:

Our company has more than 2,000 tons of coil steel stocked for ongoing orders. We stock steel of different thicknesses and grades, which allows us to fulfill any pipe production order in the shortest possible time

We produce pipes that meet all international standards and customer requirements

Our company has the ability to produce any custom order of any volume according to the customer's wishes and needs

Our team comprises seasoned professionals with extensive experience in steel pipe manufacturing and distribution. With a deep understanding of industry intricacies and cutting-edge technologies, our experts deliver uncompromising quality and reliability for your projects.

Our certificates have expiration dates and are therefore regularly updated, which is an additional incentive to maintain an appropriate level of production and comply with all technological procedures and regulations. During the production process, our specialists carry out control at every stage, all processes are automated, so an output error is excluded.

Fill out the form below, and our team will get back to you promptly. Whether you have inquiries about our products, need a quote, or want to explore partnership opportunities, we're here to assist you.

Your message matters, and we look forward to hearing from you!